The EPC-DY electro-hydraulic rectification system and the EPC-QY gas-liquid rectification system are systems that control the position deviation of the coil in the production line when it is transferred. With automatic detection, automatic follow-up, automatic adjustment and other functions. It can track and correct the marking lines or edges of paper, film, adhesive tape, aluminum foil and other materials to ensure the neat winding and slitting. The system can be used in light industry, textile, printing and dyeing, printing, strip steel, non-ferrous metals and other industries. The EPC-DY type electro-hydraulic correction system adopts the infrared infrared photoelectric sensor, and the EPC-QY type gas-liquid correction system adopts the gas-sensitive sensor to detect the edge non-contact, and the hydraulic servo valve is driven after the operation of the correction control system. The hydraulic servo valve linearly distributes the hydraulic oil sucked by the pump to drive the cylinder to correct the left and right deviation, which has high accuracy and sensitivity.

|

Technical parameters

|

EPC-DY-01

|

EPC-DY-02

|

EPC-QY-01

|

|

The motor power

|

3φ380V 50HZ

|

3φ380V 50HZ

|

3φ380V 50HZ

|

|

Control the power

|

220V 50HZ

|

220V 50HZ

|

220V 50HZ

|

|

Motor speed

|

1400r/min

|

1400r/min

|

1400r/min

|

|

The motor power

|

0.75KW

|

1.5KW

|

0.55KW

|

|

Pressure of work

|

0-25kg/cm2

|

0-70kg/cm2

|

0-15kg/cm2

|

|

Tank volume

|

10L

|

40L

|

15L

|

|

The pump flow

|

5L/min

|

20L/min

|

6L/min

|

|

The cylinder diameter

|

φ40φ50φ63

|

φ63φ80φ100

|

φ40φ50

|

|

trip

|

100-450mm選用

|

100-450mm選用

|

100-450mm選用

|

|

Detection sensor

|

Photoelectric sensor

|

Photoelectric sensor

|

Photoelectric sensor

|

|

Correction accuracy

|

±0.5mm

|

±0.5mm

|

±0.5mm

|

|

Rectifying the speed

|

0-40mm/s is adjustable

|

0-40mm/s is adjustable

|

0-40mm/s is adjustable

|

|

sages

|

6000kg

|

15000kg

|

5000kg

|

|

Overall dimensions

|

450×240×500

|

450×360×530

|

450×240×510

|

|

The weight of the

|

50kg

|

75kg

|

60kg

|

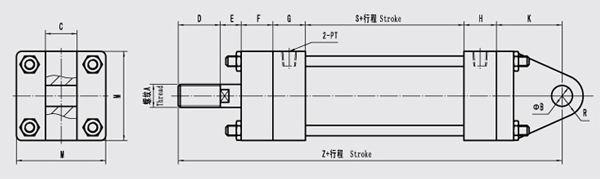

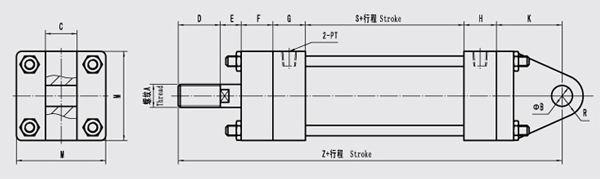

MOB - CA type hydraulic cylinder shape size

|

The cylinder diameter

|

A

|

B

|

C

|

D

|

E

|

F

|

G

|

H

|

K

|

M

|

R

|

S

|

Z

|

PT

|

|

ф40

|

M16×1.5

|

12

|

22

|

28

|

17

|

20

|

30

|

30

|

36

|

64

|

13

|

50

|

211

|

ZG3/8

|

|

ф50

|

M16×1.5

|

16

|

22

|

28

|

18

|

20

|

30

|

30

|

36

|

70

|

16

|

50

|

211

|

ZG3/8

|

|

ф60

|

M22×1.5

|

20

|

30

|

40

|

20

|

30

|

31

|

31

|

46

|

85

|

20

|

50

|

248

|

ZG3/8

|

|

ф80

|

M26×1.5

|

30

|

30

|

40

|

20

|

32

|

37

|

37

|

68

|

106

|

30

|

55

|

289

|

ZG1/2

|

|

ф100

|

M30×1.5

|

35

|

35

|

45

|

20

|

32

|

37

|

37

|

73

|

122

|

35

|

80

|

324

|

ZG1/2

|

|